The responsiveness of the local industry to produce hydroalcoholic gel and health protection masks was praised. RPE-OI takes a further step by establishing itself over the long term. Paul Soubaya tells the story of this project put together in record time.

February 8, 2021, the decision falls : children must wear a mask from first grade. Ten days later, Paul Soubaya, founder of Réunion Protection Environnement Indian Ocean (RPE-OI) organizes a press conference to announce that 700,000 children's masks have already left the clean room of its mask production workshop, on the ZAC Grand Canal in Saint-André… The RPE-OI production tool has been adapted for children. Exemplary responsiveness. But behind this reactivity lies above all the extreme speed with which the RPE-OI company itself was born.. The company was created in May 2020. The factory started operating in September. Five months later !

In five months, Paul Soubaya set up a team, bought machines, overcame technical mastery problems, passes all stages of health compliance and administrative regulations, trained staff, adapted the premises and created a production “clean room”… A record and a performance. To understand, we must first recall the journey of Paul Soubaya, founder of the company Réunion Valorisation Environnement, specialized in the recycling of waste electrical and electronic equipment. “My father was a farmer, recalls Paul Soubaya. Nature protection, he instilled it in me throughout my youth. When I was a computer scientist, I replaced the companies' computer parks. This is how I became aware of the end of life of all these used devices. I created RVE in 2006 on an area of 1000 square meters with two employees at the start. Today there are 160 of us and we occupy 26,000 square meters. »

The launch of the project

In 2020, the pandemic. The question arises as to how to equip RVE’s 160 employees with protective masks and gloves.. In March, Paul Soubaya is on vacation abroad when the first confinement occurs. “I was at the window of my hotel room and, suddenly, I wondered if this was not the opportunity to create a surgical mask manufacturing unit. » Fifteen days later, he is back in Reunion. The informs himself, brings together his management team, relies in particular on the skills of Liz Desmedt, QSE manager (Quality Safety Environment) by RVE. “Create a clean room, obtain certifications, find the machines, finance the whole : technically, it was possible. also legally. At the beginning of April, I launched the project. »

The product is chosen and designed : it will be a three-ply mask with nose clip and elastic, five layers of fabric for optimal filtration, single use, non-medical. Company and product names, Understand, are decided jointly at a meeting. Premises are set up. A 400 m² clean room guaranteeing a healthy and certified atmosphere is created. “We started from a blank page with the desire to move quickly, but good. We immediately had the production room built. In July, the machines arrived from China. Everything was written in Chinese. We brought a consultant from mainland France for three months to prepare them and train us. »

in parallel, RPE-OI has passed all regulatory steps authorizing it to produce protective masks : product effectiveness, traceability management, management of health safety in clean rooms, European CE standard…

The project is evolving

Produce masks, it's perfect, but seems insufficient to sustain the activity. With the pandemic, the advantages of a more circular economy take on their full meaning and Paul Soubaya and his team then look for what other related products would find outlets and how to manufacture them. The business project is oriented upstream of the production chain, that is to say towards the production of polypropylene fabric used to make masks. New fitted room, new investment in machinery. RPE-OI is today the only local mask manufacturer to produce its first textile from plastic granules.. With this fabric, the company also began producing a range of personal protective equipment (EPI) : different sizes of charlottes, overshoes, overcoats.

for individual protection.

“The objective is to create a sustainable activity, capable of meeting Reunion’s need for autonomy in the supply of personal protective equipment, explains Paul Soubaya. The need for masks for adults and children will last. And local demand for PPE exists, between agri-food companies, analysis laboratories, research laboratories, communities, school catering, shops, etc. Companies and organizations that have imported them until now. " Result : six months after its launch, RPE-OI produces 50,000 adult masks per day, 60,000 masks for children, 70,000 shoe covers, 20,000 caps and production of overcoats begins this month. The activity starts with around ten people, mostly recruited internally. At term, it should generate 20 to 25 jobs.

What to do with used masks ?

This question, a recycling specialist couldn't not ask this question. At present, used protective masks end up in the gray trash, i.e. landfill. Or, like other plastics, this type of plastic textile can be recycled : not to produce mask cores, but for other uses. RPE-OI is only just beginning, but the end of life of masks and other personal protective equipment would clearly fall within its vocation. The first step would be to organize the collection. Nothing is decided yet, but Paul Soubaya says he is thinking about recovery terminals that would be installed in schools and supermarkets. In summary, RPE-OI has certainly not finished surprising us.

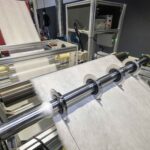

Photo caption RPE 1

Clean room production takes place in a controlled atmosphere.

Photo caption RPE 83

Paul Soubaya extends his activity from recycling to personal protection.

Photo caption RPE 44 or 47

At term, RPE-OI should create 20 to 25 jobs.

Photo caption RPE 79

Liz Desmedt, QSE manager

Product photo RPE 39

(without legend)

Photo caption 50

Mask production machines come from China.

Photo caption RPE 70 and 76

RPE-OI manufactures its own fabric, a non-woven fabric made from polypropylene granules.